We Rebuild All Makes and Models of Turbochargers for Automotive, Diesel, Marine and Industrial Applications.

Gillett Diesel Service has been rebuilding and remanufacturing used turbochargers since 1989 and is now accomplishing this in our modern facility in Bluffdale, Utah.

We are committed to rebuilding to factory standards and our processes and procedures are designed to produce a quality product that will meet or exceed our customers' expectations.

Gillett Diesel Service backs up that commitment with a one-year, unlimited milage warranty on the Automotive, Diesel, Marine and Industrial turbochargers. This assures the customer that the rebuilt turbocharger will perform like new.

If the turbocharger in your vehicle is no longer performing properly and is ready to be replaced, there is no need to purchase a new factory turbocharger. Your existing turbocharger can be rebuilt to OEM specifications. Rebuilding or remanufacturing your existing turbocharger, instead of purchasing a new one, can save you 30 to 40 percent.

Gillett Diesel Service has a large inventory of rebuilt cores that are available for same day shipment. If the required model core is not in stock, Gillett Diesel Service can remanufacture and make shipment within one to two business days, saving extended vehicle down time.

Commitment to Quality

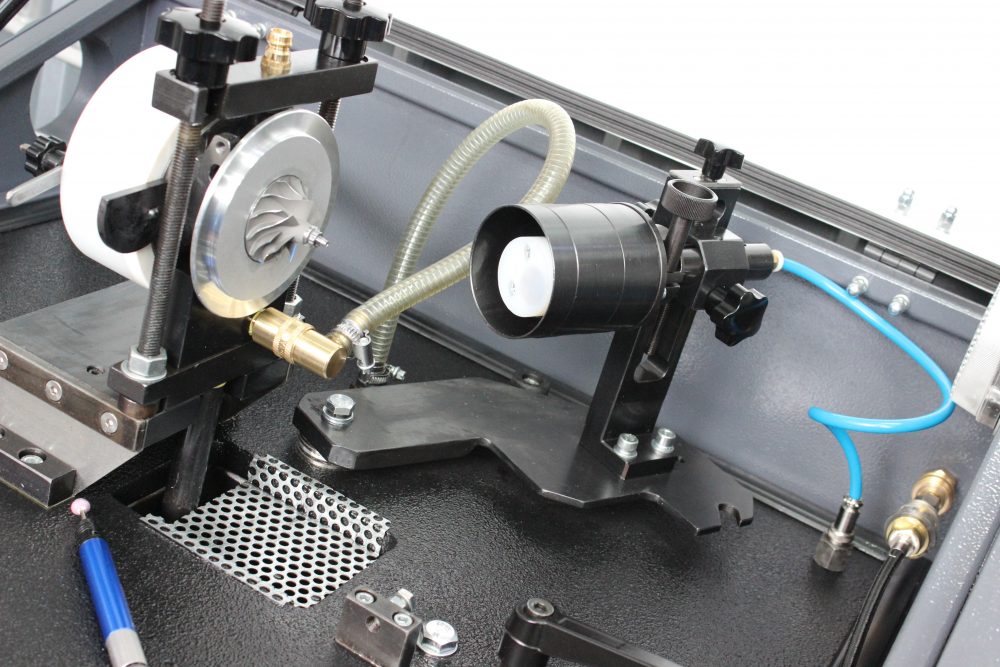

Gillett Diesel Service only uses parts that meet or exceed all factory standards. In addition to the use of high quality parts, every turbo rebuild or upgrade includes individual component and rotor group balancing to ensure trouble-free operation and product performance.

Turbocharger Rebuild Procedure

The repair procedure for a turbocharger typically involves the following steps:

1. Inspection: The technician visually inspects the turbocharger to identify any signs of damage, such as cracks, leaks, or worn components.

2. Disassembly: The turbocharger is taken apart, and the components are cleaned and inspected individually to identify any damages that might not be visible during a visual inspection.

3. Replacement: Any damaged components that need to be replace are identified, and new parts are acquired and installed. These components include bearings, thrust bearing, seals, or gaskets.

4. Reassembly: The cleaned and repaired components are assembled back into the turbocharger, with new gaskets, bearings, retaining rings, thrust bearing, seals and other components that did not pass inspection.

5. Balancing: The rotating turbine and compressor components of the turbocharger must be balanced to ensure smooth operation, minimize vibration, and extend the life of the turbocharger.

6. Shipping/Local Delivery: Once the turbocharger has passed our quality control processes, it can be installed back into the vehicle or equipment it came from.